Decifrando o modelo de ângulo de fixação ideal: um projeto exaustivo

Ângulos de fixação — aqueles heróis anônimos da construção, também chamados de chumbadores ou chumbadores — são a base da instalação de máquinas e da integridade estrutural. Sua escolha não afeta apenas a estabilidade imediata; ela orquestra a sinfonia da longevidade e dita os gastos com manutenção no futuro. Estamos prestes a embarcar em uma exploração metódica da seleção de ângulos de fixação, equipando você com sabedoria prática para enfrentar enigmas do mundo real com confiança inabalável.

I. Decodificando a Taxonomia de Fixação de Ângulos

Os ângulos de fixação se manifestam em diversas encarnações, cada uma adaptada para aplicações distintas:

Ângulos de fixação estacionários: Projetado para unir permanentemente equipamentos a fundações com comprometimento inflexível.

Ângulos de fixação manobráveis (também conhecidos como parafusos de fundação longos): feitos para instalações temporárias onde máquinas colossais suportam tremores e impactos implacáveis.

Âncoras de Expansão:Predominantemente aproveitado para ancorar aparelhos modestos e imóveis ou dispositivos periféricos.

Ângulos de fixação adesiva:Os recém-chegados a esta arena, ecoando âncoras de expansão, mas exibindo maior adaptabilidade durante a instalação.

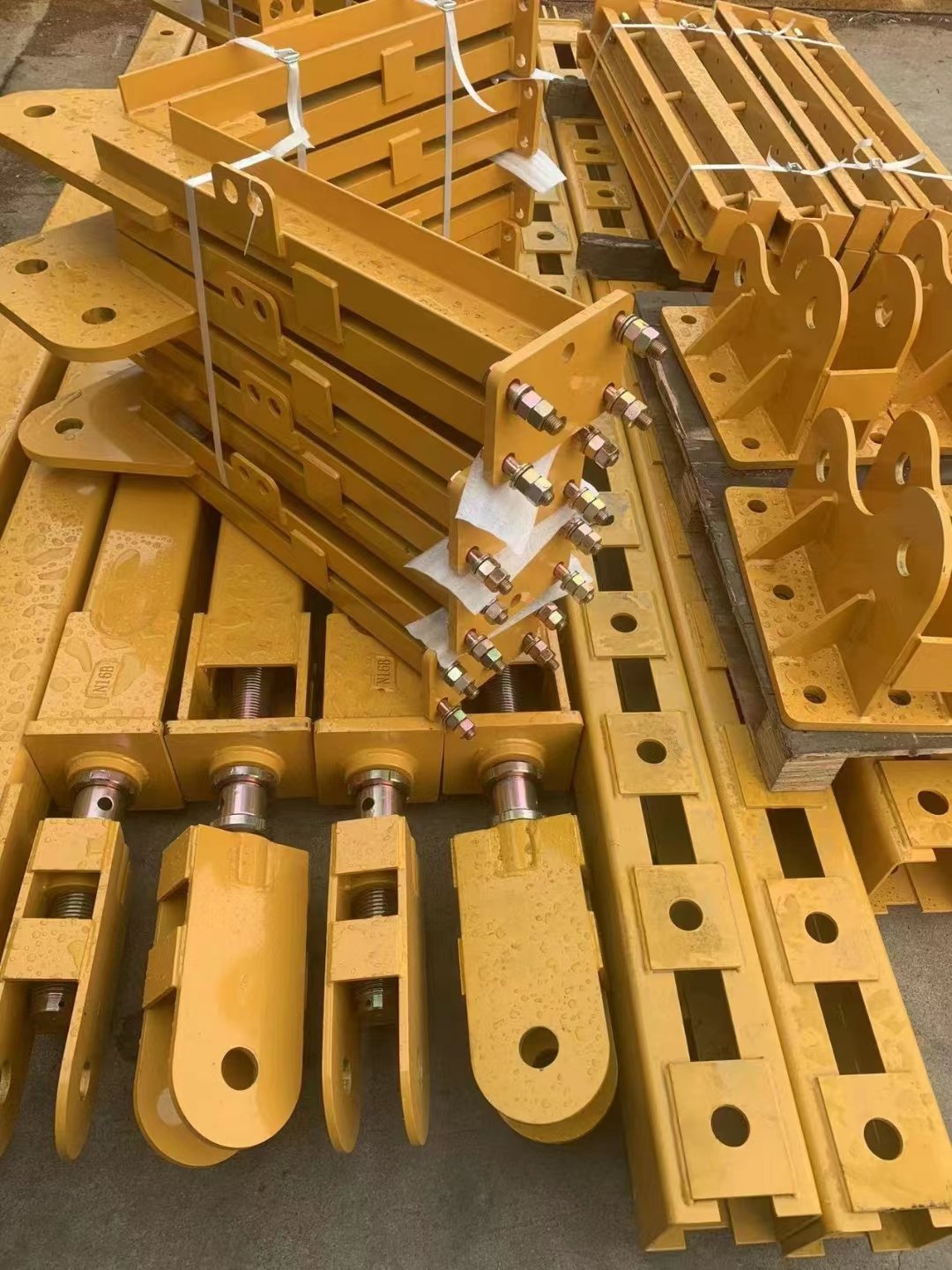

Além da categorização funcional, os ângulos de fixação exibem silhuetas variadas — variedades embutidas em formato de L, 9, U, além de suas contrapartes soldadas.

II. Parâmetros Críticos para Avaliação de Ângulos de Fixação

1. Diâmetro da rosca: a pedra angular da carga

O diâmetro da rosca de um ângulo de fixação constitui o determinante fundamental de sua capacidade de suportar peso. O espectro abrange de M6 a M30, com diâmetros crescentes correspondendo a capacidades de carga ampliadas. Sua escolha depende do peso, das dimensões e do cenário de tensões do seu equipamento alvo:

- M6 e M8: Companheiros ideais para móveis pequenos, como estantes e compartimentos removíveis.

- M10 e M12: Os modelos mais adequados para móveis de médio a grande porte — mesas, assentos, armários e estantes.

- Para gigantes industriais ou colossos estruturais como fundações de máquinas e ancoragem de torres, opte pelo M16 ou seus irmãos mais robustos.

2. Comprimento da rosca: a precisão é importante

A determinação do comprimento da rosca exige uma análise minuciosa da espessura do material a ser fixado e da profundidade de penetração necessária. A regra de ouro? O comprimento da rosca deve ser superior à espessura do material, evitando saliências excessivas que geram desperdícios e complicações desnecessárias. As medidas típicas variam de modestos 50 mm a imponentes 2.000 mm, com a seleção precisa dependendo das especificações do projeto.

3. Composição do material e melhoria da superfície

A seleção de materiais e os tratamentos de superfície influenciam profundamente as trajetórias de desempenho e as expectativas de vida útil dos ângulos de fixação. Os materiais predominantes incluem:

Variantes de aço carbono: Apresentando força e resiliência formidáveis, mas com resistência limitada à corrosão, é perfeito para ambientes áridos.

Iterações de aço inoxidável: Campeões da resistência à ferrugem, apesar dos perfis de resistência moderados — feitos sob medida para ambientes corrosivos ou com muita umidade.

Melhorias de superfície como galvanização a quente conferem maior resistência à ferrugem e intervalos de manutenção estendidos, enquanto alternativas não tratadas oferecem eficiência de custo em detrimento da vulnerabilidade à corrosão.

4. Harmonia Dimensional

As dimensões do ângulo de fixação devem estar em harmonia com o diâmetro da perna do móvel ou equipamento a ser fixado. As dimensões comuns incluem 40 mm, 50 mm e 60 mm. Conseguir um alinhamento perfeito entre o ângulo de fixação e o diâmetro da perna fortalece a estabilidade e a confiabilidade operacional.

III. Estrutura metódica para fixação da seleção de ângulos

- Requisitos de Cristalização: Identifique meticulosamente o peso, as dimensões, os padrões de estresse e o ambiente operacional da sua estrutura alvo.

- Quantificar as demandas de suporte de carga: Com base na massa do equipamento e na dinâmica de tensão, identifique as especificações apropriadas de diâmetro e comprimento da rosca.

- Deliberação de Material e Tratamento: Selecione materiais com resistência à corrosão calibrada para seu ambiente, complementados por tratamentos de superfície alinhados com suas ambições de prevenção à ferrugem.

- Verificação Dimensional: Confirme se as medidas do ângulo de fixação correspondem precisamente aos diâmetros das pernas do equipamento.

- Adesão aos Padrões: Durante as fases de seleção e implementação, consulte os padrões nacionais e industriais relevantes para garantir a qualidade do ângulo de fixação e a conformidade com o desempenho.

Fotos:

»Via Rápida«

Marcas de guindastes de torre

Capacidade do guindaste de torre

![]()

1首图.jpg)