Tower crane care and maintenance

Tower cranes are common construction equipment on construction sites. They are formally known as tower cranes and are indispensable in civil building construction, water conservancy, harbor construction, shipbuilding, and other construction operations.

Maintenance can enhance the service life of the tower crane, reduce the number of repairs as well as the failure rate, and also improve the efficiency of the tower crane driver and the progress of the project. The tower crane is regularly inspected, adjusted, lubricated, fastened, cleaned, and replenished with six tasks. This includes routine maintenance, monthly inspection and maintenance, and lubrication maintenance.

Daily maintenance is the tower crane driver's functional responsibilities, that is, responsible for before and after each shift in accordance with the provisions of the instruction manual to do maintenance work, at the same time on the temporary faults for troubleshooting and repair. Inspection is mainly based on visual inspection and functional testing. Inspections found to be difficult to solve should be promptly reported to the use of unit technicians to organize overhauls, overhauls, and maintenance, which should be recorded in the handover records. Routine maintenance focuses on cleaning, lubricating, checking, adjusting, and replacing worn parts and failed parts of the main stressed structural components, safety protection devices, working mechanisms, operating mechanisms, electrical control systems, etc. The main focuses of maintenance are to clean, lubricate, check, adjust, and replace worn parts and failed parts.

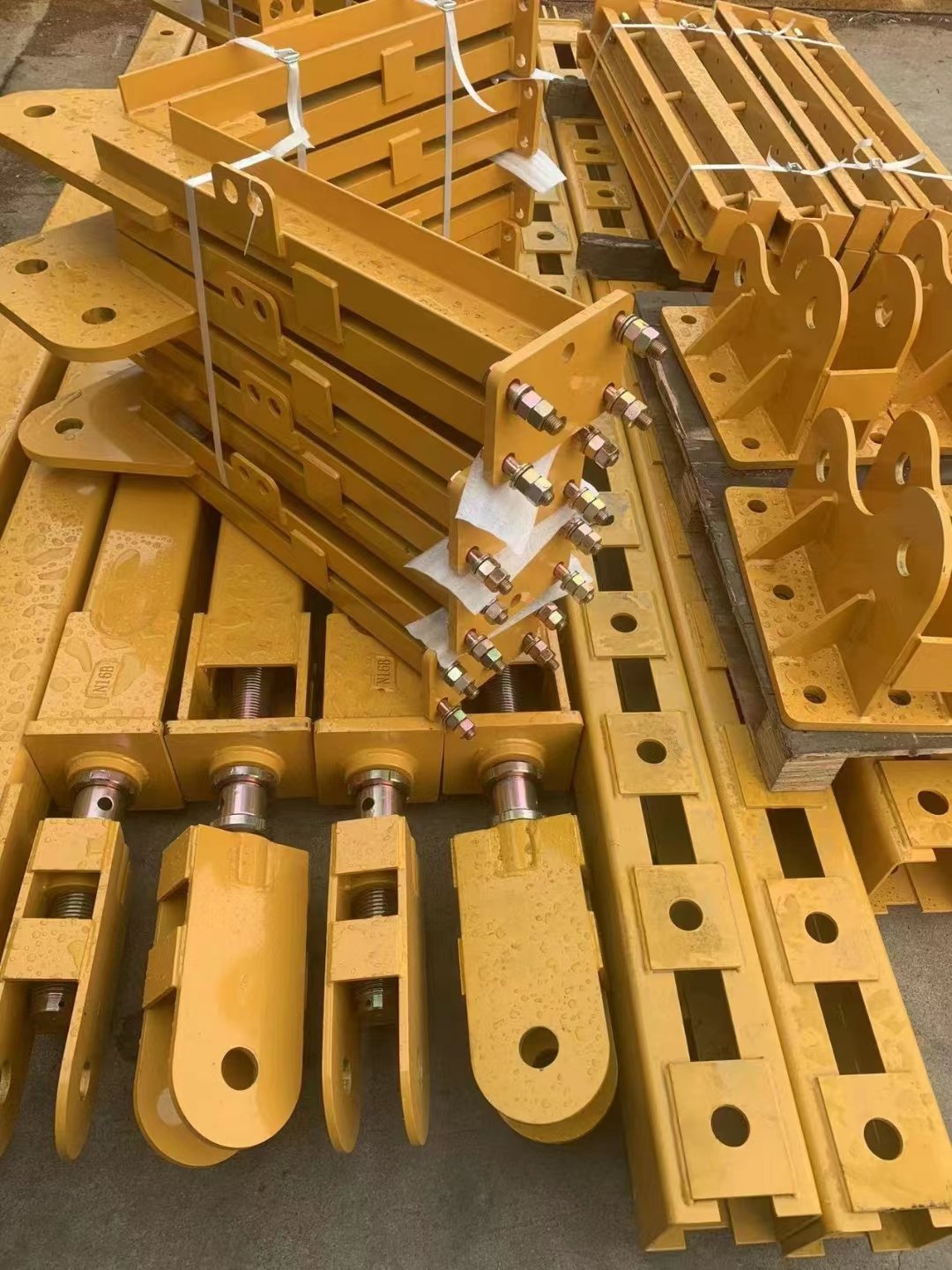

Repair and maintenance of metal structural parts

- the strict implementation of the crane steel structure scrapping standards.

- The main stressed structural components should be checked for metal fatigue strength, weld cracks, structural deformation, breakage, etc.; the main stressed structural components of the key weld and welding heat-affected zone of the parent material should be checked; if found abnormal, they should be dealt with. The inspection of structural components shall be carried out according to the following procedures:

(1) Daily inspection: the tower crane should be inspected daily every 80 hours of work. The tower crane driver shall check the tightness of the bolts of each connecting part at the time of shift handover and shall tighten them in time if they are loose.

(2) When the tower crane has an abnormal sound, has been misoperated, or the tower crane safety protection device is found to be out of order, etc., it should be inspected and a record made.

(3) When a project is completed and the tower crane is disassembled, it should be inspected in detail by engineering technicians and professional maintenance personnel, and records should be kept.

(3) During transportation, try to prevent deformation and collision damage to structural parts.

Spray paint every six months to one year. Before painting, rust spots, oil, and other dirt on the metal surface should be removed.

Tower drivers should also check the tightness of the bolts of each connection part during the shift handover, especially the parts of the mechanical bolts that are often vibrated, such as the tower frame connection bolts, which should be checked regularly to see if they are loose. If loose, they must be tightened or replaced in time.

To check the looseness of the bolts, you can install the Bocai intelligent warning nut, which is mainly used for the tower crane's nut loosening after the alarm.

time,The early warning nut installed in the tower crane fastening nut above, when the tower crane bolt loose, squeeze the upper warning nut, will trigger the alarm device, and at the same time to start the lights, continue to flash an alarm, and launch the alarm signal to the intelligent terminal through the cell phone and computer to remind the management personnel of a certain place nut being loose. When the management personnel are not on site, they can also remotely receive the warning information of the warning nut in real time, which can improve the efficiency of the inspection, maintenance, and repair of tower crane bolts.

The main stressed structural components should be checked for metal fatigue strength, weld cracks, structural deformation, breakage, etc. The key welds of the main stressed structural components and the base material of the welded heat-affected zone should be inspected, and if any abnormality is found, it should be dealt with.

transportation,In the process of transportation it is important to try to prevent structural deformation and collision damage. When the tower machine appears to have an abnormal sound, there has been misoperation, or it has been found that the tower machine safety protection device has failed, etc., it should be inspected, and a record should be made as soon as possible to deal with it!

![]()