Loyihalaringiz uchun kran quvvatini tushunish

Loyihalaringiz uchun kran quvvatini tushunish

In the world of construction and heavy lifting, understanding crane capacity is fundamental to the success and safety of any project. The term crane capacity refers to the maximum weight a crane can safely lift, and it varies significantly based on the type of crane, configuration, and operating conditions. Whether you are working with a tower crane capacity for high-rise construction or evaluating the boom truck capacity for transportable lifting tasks, knowing these details ensures efficient and risk-free operations. In this article, we explore the essentials of crane lifting capacity, the factors influencing it, and how to optimize crane use tailored to your project needs.

The Basics of Crane Lifting Capacity

Crane lifting capacity is a critical specification that guides engineers and project managers in selecting the right crane for their worksite. Each crane model comes with a rated load chart, indicating how much weight it can lift at various boom lengths and angles. These limits are not arbitrary; they are based on structural strength, mechanical design, and safety considerations. For example, a tower crane capacity will differ greatly from that of a mobile boom truck due to their structural design and intended applications. Understanding these distinctions is key to avoiding overloading, which can lead to accidents and equipment damage.

Moreover, crane capacity is often expressed in tons or kilograms, and it is crucial to account for the load’s weight including rigging and lifting accessories. This comprehensive approach ensures that the crane operates within safe margins. Planning with precise knowledge of crane lifting capacity also helps optimize project timelines by avoiding delays caused by equipment mismatch or overestimation of crane capabilities.

Modern cranes incorporate advanced technology to assist operators in monitoring load weights in real-time, enhancing safety and operational efficiency. Such technologies are instrumental in maintaining adherence to capacity limits during dynamic lifting scenarios.

Factors Influencing Crane Capacity

Several factors affect the effective crane capacity on any given job site. The most prominent include the boom length, boom angle, and radius of the lift. As the boom extends or the radius increases, the crane’s lifting capacity decreases due to leverage effects. This relationship is reflected in the crane’s load charts and must be carefully analyzed during project planning.

Environmental conditions also play a role. Wind speed, ground stability, and temperature can impact crane performance and capacity. For example, strong winds can impose additional forces on the lifted load and crane structure, necessitating capacity derating for safety. Similarly, unstable or soft ground requires proper crane setup with mats or outriggers to maintain stability and preserve rated capacity.

Maintenance and mechanical condition of the crane are equally important. Regular inspections and prompt servicing ensure that the crane’s structural integrity and hydraulic systems function optimally, supporting consistent lifting capacity. Neglecting maintenance can degrade performance and compromise safety.

Project-Specific Requirements and Planning

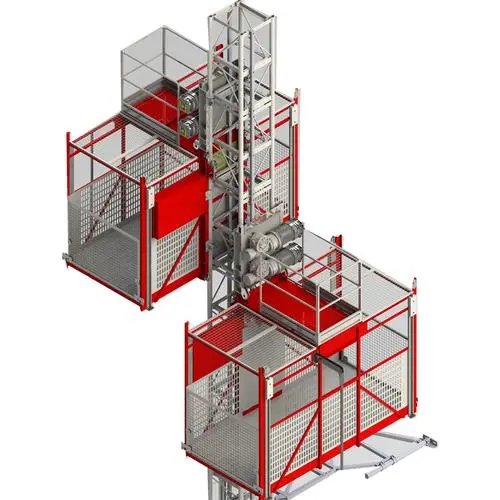

Each construction or industrial project has unique lifting requirements that dictate the choice of crane and its capacity. Large-scale projects involving heavy structural components often require cranes with very high capacity and reach, such as tower cranes capable of lifting several tons at great heights. Conversely, smaller projects or those requiring frequent relocation might benefit from boom trucks with moderate lifting capacity but superior mobility.

Project managers must assess the weight and dimensions of the heaviest loads, the lift height, and the working radius to match a crane that can safely handle all operational demands. Additionally, understanding Mahsulotlar available, such as those from industry leaders like Foshan Yueyang Machinery, can provide insight into finding cranes that balance capacity with cost-effectiveness and reliability.

Effective planning also includes contingency measures for unexpected load variations and environmental changes. Incorporating expert input and utilizing simulation software can improve accuracy in crane capacity planning and deployment.

Technology and Expertise Enhancing Crane Capacity Use

Advancements in crane technology have revolutionized how capacity is managed and optimized. Load moment indicators, anti-two block devices, and remote monitoring systems provide operators with real-time data to prevent overloads and improve lift precision. These technologies contribute to safer and more efficient project execution.

Professional expertise is indispensable in interpreting load charts, conducting site assessments, and configuring cranes optimally. Experienced operators and riggers understand the nuances of different crane types and how environmental and operational factors affect lifting capacity. Their skills ensure that cranes are used within their limits while maximizing productivity.

Training and certification programs for crane operators emphasize capacity knowledge and safe handling practices, further reinforcing workplace safety and compliance with regulations.

Optimizing Crane Configurations for Maximum Efficiency

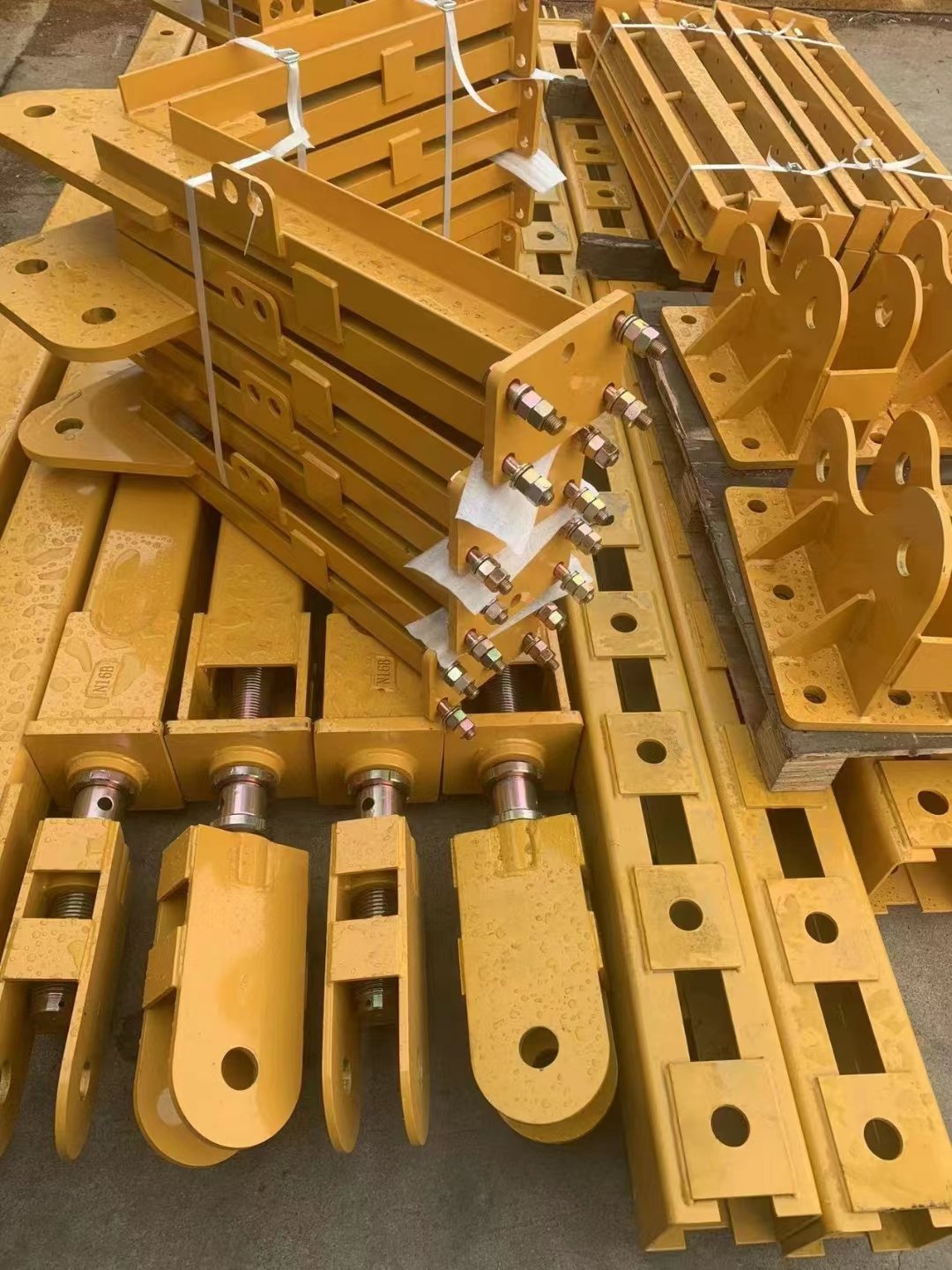

Optimizing crane configurations involves selecting the best combination of boom length, counterweights, and outriggers to achieve the required capacity safely. For instance, using additional counterweights can increase a crane’s lifting ability, but must be balanced against transport and setup constraints.

Regularly reviewing crane configurations as project demands evolve can help maintain efficiency and safety. Adjusting boom lengths or relocating cranes to better positions can reduce lift radius and increase effective capacity. This adaptability is crucial in complex projects with changing lifting profiles.

Foshan Yueyang Machinery, recognized for their engineering excellence and competitive advantages in the crane market, offers tailored solutions to optimize crane setups, ensuring clients receive equipment that meets specific project challenges with superior performance.

For companies seeking reliable cranes and detailed consultation, visiting the BIZ HAQIMIZDA page offers insights into providers committed to quality and innovation in crane technology.

Conclusion: The Importance of Understanding Crane Capacity

Understanding crane capacity is indispensable for successful project execution, safety, and cost management. From knowing the basics and factors affecting capacity to the application of technology and expert knowledge, every aspect plays a role in optimizing crane use. Whether dealing with tower crane capacity or evaluating the boom truck capacity for mobile lifts, detailed planning based on precise capacity knowledge mitigates risks and drives efficiency.

Working with reputable machinery providers such as Foshan Yueyang Machinery ensures access to quality equipment and professional support, enhancing project outcomes. For further inquiries or customized service offerings, visiting the BIZ BILAN BOG'LANISH page is recommended to connect with experts in crane solutions.

![]()