Sicurezza delle gru a braccio girevole: nuove informazioni sull'allerta vento

Sicurezza delle gru a braccio girevole: nuove informazioni sull'allerta vento

Introduzione: comprendere il significato degli avvisi di sicurezza delle gru a braccio girevole

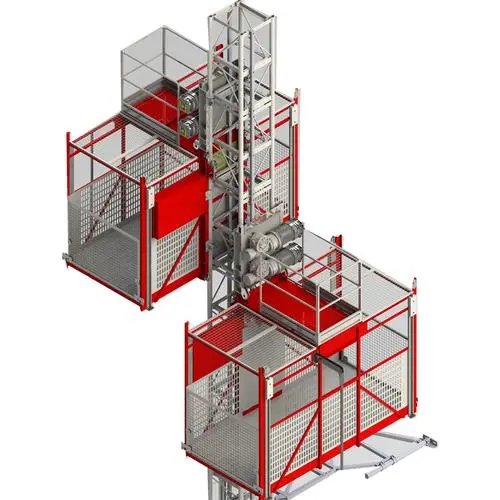

Le gru a braccio impennabile sono attrezzature essenziali nell'edilizia moderna, offrendo flessibilità e precisione nelle operazioni di sollevamento grazie al loro caratteristico meccanismo di braccio impennabile. Recentemente, sono stati emessi nuovi avvisi di sicurezza riguardanti l'utilizzo delle gru a braccio impennabile in condizioni di vento forte, sottolineando l'importanza fondamentale del rispetto delle linee guida operative per prevenire incidenti. Questi avvisi servono come promemoria tempestivo per gli operatori di gru, i responsabili di cantiere e gli addetti alla sicurezza affinché rivedano i loro protocolli di sicurezza, in particolare nelle regioni soggette a venti imprevedibili e ad alta velocità. L'attenzione per le gru a braccio impennabile nasce dal loro design unico, che può essere più suscettibile agli impatti del vento rispetto ad altri tipi di gru, come le gru a torre con braccio impennabile o le gru a torre con braccio impennabile.

Garantire il funzionamento sicuro delle gru a braccio girevole non è solo fondamentale per la protezione del personale e delle attrezzature, ma anche per rispettare le tempistiche di progetto e ridurre al minimo le perdite finanziarie causate da incidenti. Foshan Yueyang Machinery, produttore leader noto per le sue soluzioni di gru di qualità, sottolinea l'importanza di integrare misure di sicurezza basate sulla gestione del rischio vento. Questo articolo esplora il contesto degli incidenti alle gru correlati al vento, offre linee guida pratiche sulla sicurezza, esamina i registri storici degli incidenti e delinea misure preventive e normative per favorire la conformità e promuovere cantieri più sicuri.

Contesto dell'incidente: l'impatto dei forti venti sulla sicurezza delle gru a braccio girevole

I venti forti hanno storicamente rappresentato gravi rischi per la stabilità e il funzionamento sicuro delle gru a braccio mobile. A causa della loro capacità di variare l'angolazione del braccio, le gru a braccio mobile possono essere vulnerabili alle forze del vento che possono causare movimenti incontrollati, sollecitazioni strutturali o persino ribaltamenti. Incidenti passati hanno dimostrato che, senza adeguate precauzioni, condizioni di vento forte possono causare danni alle apparecchiature e gravi rischi per la sicurezza. Ad esempio, raffiche improvvise possono causare oscillazioni imprevedibili del braccio mobile, mettendo a dura prova il controllo dell'operatore e aumentando il rischio di collisione con strutture o lavoratori nelle vicinanze.

In Australia e in altre regioni con condizioni climatiche variabili, diversi incidenti con gru sono stati attribuiti a una risposta inadeguata alle allerte vento o alla mancata attuazione di appropriate restrizioni operative in condizioni meteorologiche avverse. Questi eventi sottolineano la necessità di rigorosi protocolli operativi in caso di vento e di un monitoraggio continuo delle condizioni del vento. La comprensione di questi rischi costituisce la base per lo sviluppo di linee guida che garantiscano l'utilizzo sicuro delle gru a braccio girevole in diverse condizioni ambientali.

Linee guida di sicurezza: banderuola e raccomandazioni operative in condizioni ventose

Una delle principali pratiche di sicurezza per la gestione del funzionamento della gru a braccio mobile in condizioni di vento è la banderuola. La banderuola consente alla gru di ruotare liberamente per allinearsi alla direzione del vento, riducendo così la resistenza al vento ed evitando sollecitazioni eccessive sulla struttura della gru. Gli operatori devono essere formati per abilitare e monitorare questa funzione, assicurandosi che il braccio della gru non sia bloccato in una posizione fissa in presenza di vento forte.

Oltre alla banderuola, le linee guida operative raccomandano di interrompere le attività di sollevamento una volta che la velocità del vento raggiunge limiti predefiniti, in genere specificati nel manuale del produttore della gru o nelle norme di legge. Ad esempio, le gru a braccio mobile possono avere limiti di velocità del vento intorno ai 20-25 metri al secondo, oltre i quali tutte le operazioni della gru dovrebbero essere sospese. Il monitoraggio regolare della velocità del vento tramite anemometri installati in loco è fondamentale, e la comunicazione in tempo reale tra l'operatore della gru, il segnalatore e il supervisore del cantiere è necessaria per una risposta immediata alle mutevoli condizioni.

Per prevenire sollecitazioni eccessive sulla struttura della gru, è necessario garantire che tutti i carichi siano correttamente bilanciati e che non si verifichino sollevamenti in caso di raffiche di vento o venti imprevedibili. Anche l'utilizzo di vele o barriere frangivento in loco può mitigare l'effetto del vento, soprattutto in luoghi esposti. Queste misure di sicurezza riducono il rischio di incidenti e contribuiscono alla longevità dei componenti meccanici della gru.

Registro degli incidenti: resoconti storici delle sfide relative alla sicurezza delle gru a braccio girevole nelle giurisdizioni australiane

In Australia si sono verificati diversi incidenti che hanno coinvolto gru a braccio mobile colpite da forti venti, documentati in diverse giurisdizioni, tra cui Queensland, Nuovo Galles del Sud e Victoria. I rapporti di WorkSafe Queensland indicano che diversi incidenti sono stati direttamente collegati a insufficienti precauzioni contro il vento, con conseguenti danni alla gru e infortuni sul lavoro. Un caso degno di nota ha riguardato una gru a torre con braccio mobile che è crollata dopo che forti venti prolungati hanno causato un guasto al meccanismo di bloccaggio del braccio.

L'analisi di questi incidenti rivela fattori comuni come una formazione inadeguata sui protocolli di sicurezza in caso di vento, la mancanza di applicazione delle pratiche di segnalazione e il mancato rispetto dei limiti di velocità del vento stabiliti dai produttori. Questi problemi ricorrenti hanno spinto gli enti regolatori a rafforzare i requisiti di sicurezza e ad aumentare le campagne di sensibilizzazione incentrate sulla sicurezza delle gru in caso di vento. L'accumulo di dati sugli incidenti fornisce preziose lezioni per tutti gli operatori di gru e le imprese edili che mirano a migliorare i propri standard di sicurezza e la conformità.

Misure preventive: vele a vento, pratiche di sollevamento e strategie di sicurezza avanzate

Per prevenire incidenti dovuti al vento, molti cantieri edili hanno adottato tecnologie preventive come le vele antivento, grandi barriere regolabili progettate per ridurre la forza del vento sulle gru a braccio mobile. Queste vele aiutano a stabilizzare il braccio della gru e a ridurre al minimo l'oscillazione, particolarmente utili negli ambienti urbani dove gli effetti della galleria del vento possono amplificare le raffiche. Inoltre, le pratiche di sollevamento adattate alle condizioni del vento includono la riduzione del peso e dell'altezza del carico durante i periodi ventosi per ridurre il rischio di instabilità.

Foshan Yueyang Machinery raccomanda l'integrazione di sistemi di monitoraggio avanzati che combinano sensori di velocità del vento con regolazioni automatiche del controllo della gru, consentendo modifiche operative immediate in risposta alle fluttuazioni meteorologiche. Anche le routine di manutenzione e ispezione regolari, incentrate sui componenti strutturali interessati dalle sollecitazioni del vento, come i punti di articolazione e i perni di bloccaggio del braccio mobile, sono fondamentali per preservare l'integrità della gru. Grazie a queste misure combinate, gli operatori possono garantire operazioni di sollevamento più sicure e ridurre i tempi di fermo causati da interruzioni dovute alle condizioni meteorologiche.

Norme normative: limiti di velocità del vento e conformità per le operazioni delle gru a braccio girevole

Il rispetto degli standard normativi è fondamentale per garantire il funzionamento sicuro delle gru a braccio girevole in caso di vento forte. Gli standard australiani, come quelli definiti da Safe Work Australia e WorkSafe Queensland, specificano le velocità massime del vento consentite per il funzionamento delle gru, generalmente comprese tra 20 e 25 metri al secondo a seconda del modello e della configurazione. Questi standard impongono inoltre agli operatori di effettuare valutazioni dei rischi e di stabilire protocolli di monitoraggio del vento specifici per ogni sito.

Produttori come Foshan Yueyang Machinery forniscono manuali operativi dettagliati che includono soglie di velocità del vento e controlli di sicurezza. Gli operatori devono familiarizzare con queste linee guida e assicurarsi che tutte le attività delle gru a torre con braccio impennabile vengano sospese quando le condizioni del vento superano i limiti di sicurezza. La conformità normativa non solo riduce il rischio di incidenti, ma protegge anche le aziende da responsabilità legali e migliora la cultura generale della sicurezza sul lavoro.

Conclusione: il ruolo fondamentale dei protocolli di sicurezza e della collaborazione tra produttori e operatori

In conclusione, il recente avviso di sicurezza per le gru a braccio girevole rappresenta un invito fondamentale all'azione per tutti gli attori coinvolti nelle operazioni con le gru. Riconoscere i rischi posti dai forti venti e attenersi scrupolosamente alle pratiche di segnalazione, ai limiti operativi di velocità del vento e alle misure preventive è essenziale. Produttori come Foshan Yueyang Machinery svolgono un ruolo fondamentale fornendo attrezzature robuste e chiare linee guida di sicurezza, mentre operatori e responsabili di cantiere devono applicare diligentemente questi protocolli.

Promuovendo una cultura della sicurezza, garantendo una formazione continua e impiegando ausili tecnologici come vele eoliche e sistemi di monitoraggio, il settore edile può mitigare significativamente i rischi legati al vento associati alle gru a braccio girevole. Per ulteriori informazioni sui prodotti e servizi per la sicurezza delle gru, consultare il sito Prodotti La pagina offre risorse e soluzioni preziose studiate per migliorare la sicurezza e l'efficienza operativa.

Argomenti e tag correlati

- WorkSafe Queensland

- Sicurezza della gru

- Venti forti

- Conformità

- Fiocco impennabile

- Gru a torre con braccio impennabile

- Boom che si solleva

![]()