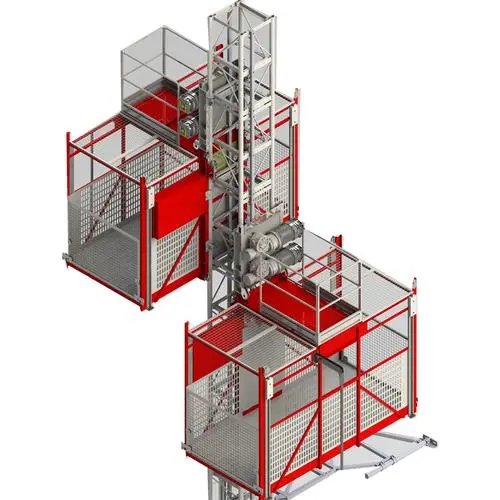

2023 XCMG XGL300-18S 18т башенный кран с подъемной стрелой на продажу

Башенный кран с подъемной стрелой XCMG б/у XGL300-18S разбирается, сделан только проект на месте, производительность очень превосходная, машина совсем новая.Юэян машины в первый раз, когда мы его демонтируем, делаем нашу стандартную машину, профессиональное обслуживание для наших клиентов, чтобы предоставить кран с подъемной стрелой первоклассного выбора.

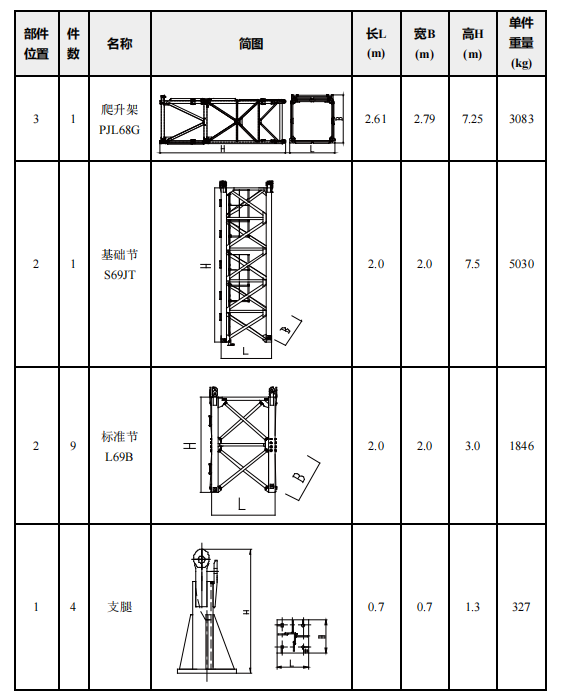

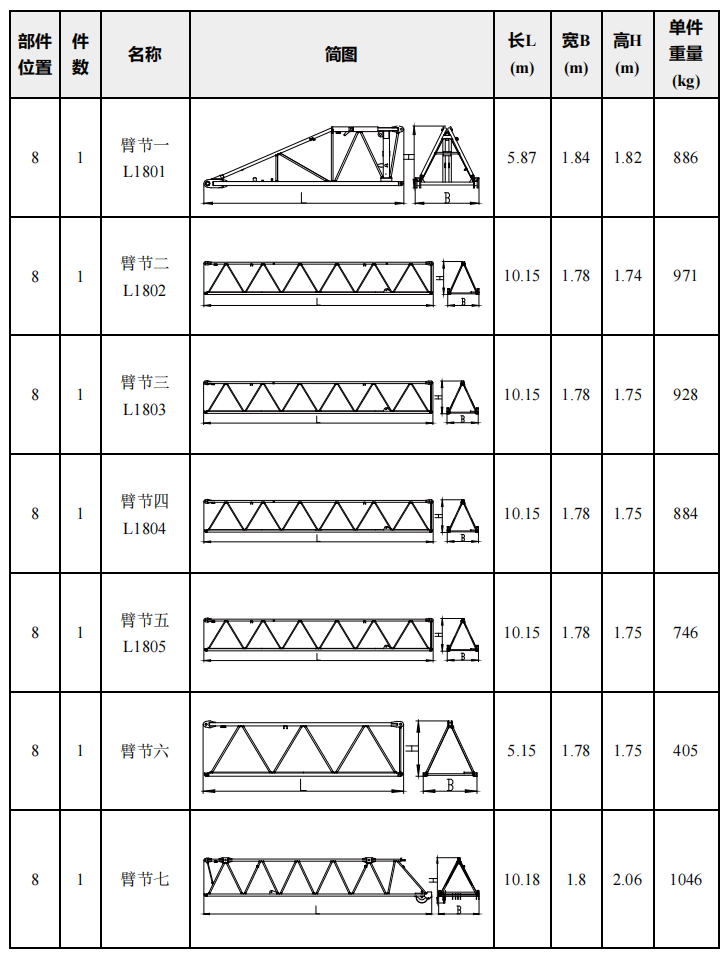

Технические характеристики крана XGL300-18S

| Проект | Единица | XGL300A-18S |

|---|---|---|

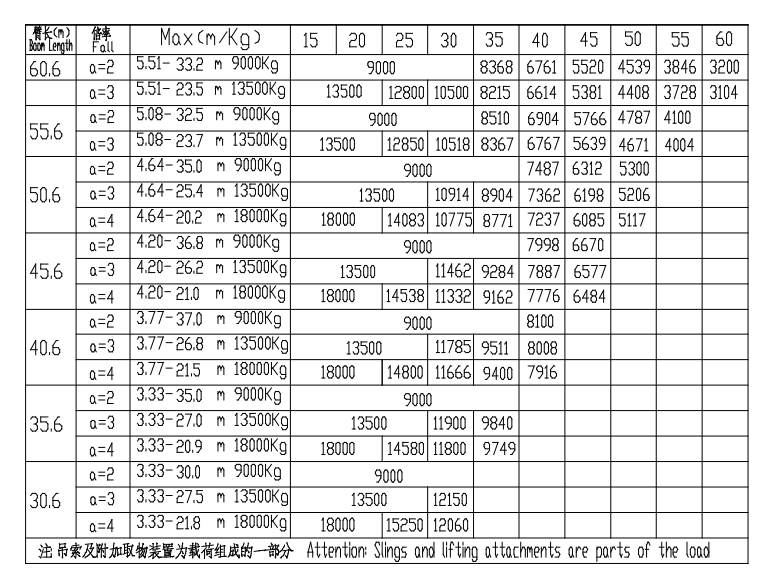

| Длина стрелы/нагрузка на конце стрелы | м/т | 60/3.2 |

| Номинальный момент нагрузки | т·м | 300 |

| Максимальная грузоподъемность | т | 18 |

| Максимальная независимая высота | м | 46.1 |

| Максимальная прикрепленная высота | м | 199.1 |

| Грузоподъемность подъемного каната | м | 805 |

| Максимальная скорость подъема | м/мин | 100 |

| Время изменения вылета стрелы (15°~85°) | — | ≤2,5 мин |

| Скорость поворота | об/мин | 0~0.7 |

| Подъемная мощность | кВт | 67 |

| Мощность подъема стрелы | кВт | 45 |

| Мощность поворота | кВт | 2×7,5 |

Башенный кран XGL300-18S Введение

- Первое в отрасли применение высокопрочной холодногнутой стали, более легкая стрела, более высокая грузоподъемность по сравнению с другими производителями в той же отрасли, а уровень легкости является ведущим в отрасли;

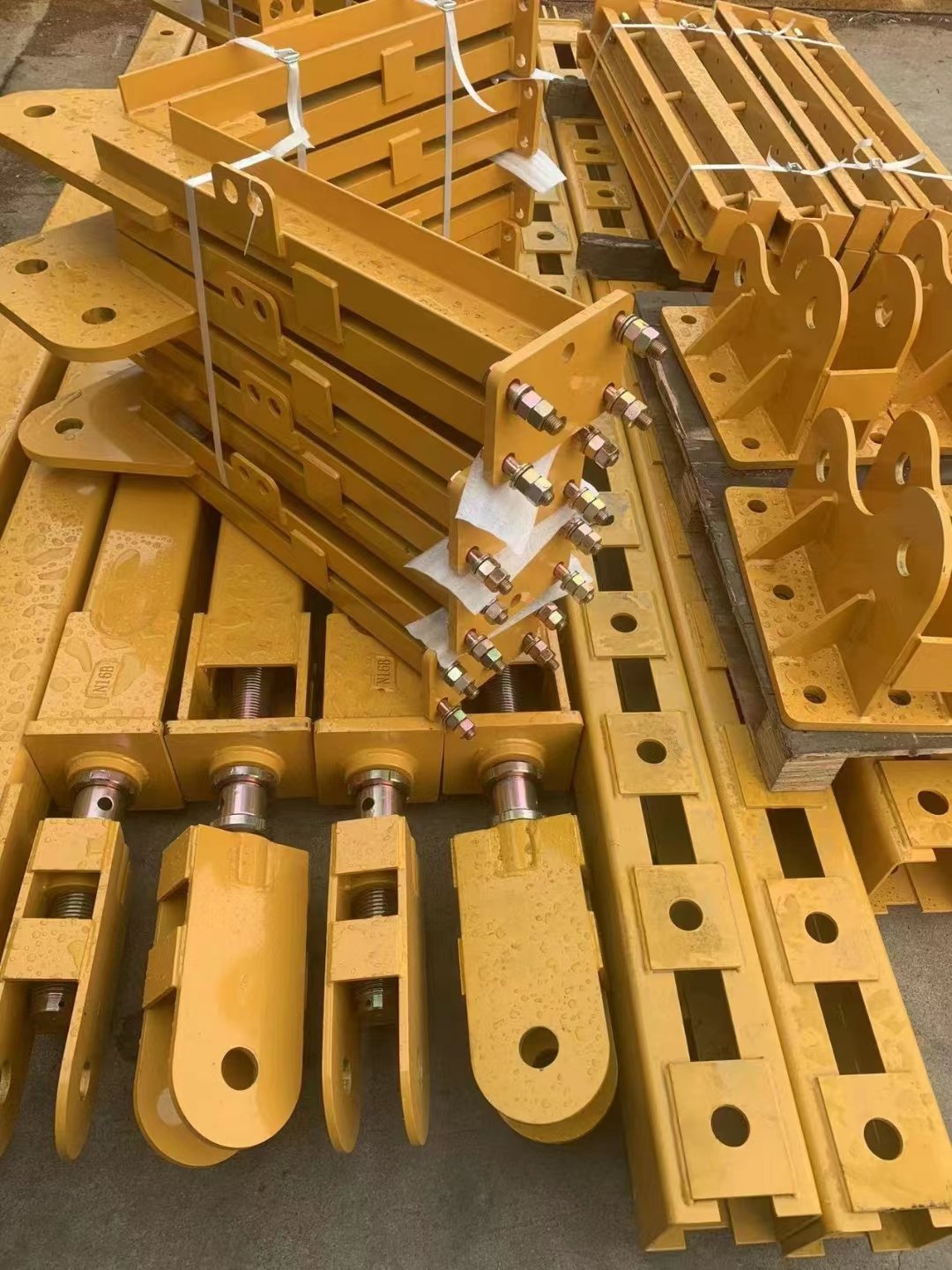

- Вся машина оснащена высокопрочными болтами Dacromet класса прочности 8.8-10.9, которые обладают повышенной прочностью, более высокой устойчивостью к ржавчине и более длительным сроком службы;

- Детали конструкции выполнены по технологии электростатического напыления порошка, покрытие уровня автомобильного класса, не выцветает в течение 2 лет, не ржавеет в течение 5 лет;

- Вся платформа машины изготовлена из алюминиевого сплава и никогда не ржавеет;

- Впервые концепция дизайна кабины, разработанная в автомобильной отрасли, была внедрена в отрасль башенных кранов, а процесс обработки электрофорезом был использован для достижения десятилетней защиты кабины от ржавчины;

- Наружный блок кондиционера встроен, а общая безопасность установки и транспортировки позволяет избежать повреждения внешней машины и снизить риск наружной установки и операций по техническому обслуживанию;

- Модульная подъемная технология всей машины значительно повышает эффективность монтажа и демонтажа 20-30%;

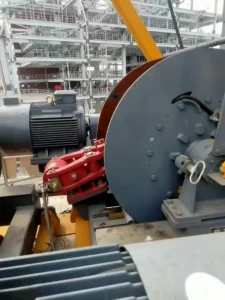

- Метод управления полным преобразованием частоты обеспечивает гибкую работу каждого механизма без воздействия, является экологичным, эффективным и интеллектуальным;

- Лучшая в отрасли функция отслеживания скорости нагрузки и технология управления скоростью червячного привода отвечают потребностям быстровозводимых зданий;

- Для вспомогательных деталей, опираясь на национальные институты контроля качества, достигается трехуровневый охват диапазона испытаний продукции, а также обеспечивается профессиональная проверка партии ключевых деталей, таких как сырьевые материалы, высокопрочные болты и штифты;

- Все вспомогательные части всей машины поставляются двумя ведущими производителями в отрасли.

"Быстрый трек"

Марки башенных кранов

Грузоподъемность башенного крана

![]()

1首图.jpg)