Các bước chính để bảo trì và bảo dưỡng cần cẩu tháp

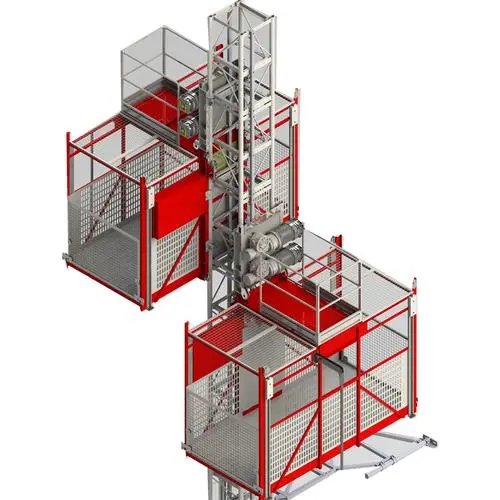

Cẩu tháp là thiết bị thi công phổ biến trên các công trường xây dựng. Chúng chính thức được gọi là cần cẩu tháp và không thể thiếu trong xây dựng công trình dân dụng, thủy lợi, xây dựng bến cảng, đóng tàu và các hoạt động xây dựng khác.

Làm thế nào để bảo trì cần trục tháp?

Mặc dù mỗi công trình đồ sộ đều mang trong mình những đặc điểm kỹ thuật riêng, và không có hai công trình nào giống hệt nhau, nhưng việc chăm sóc chúng đều có chung một hệ thống nghi lễ thiết yếu. Tuân thủ nghiêm ngặt bản thiết kế do nhà sản xuất ban đầu khắc vẫn là điều răn cốt yếu. Tuy nhiên, bên dưới mái vòm đó, năm hành động cơ bản duy trì sức sống của chúng và ngăn chặn sự sụp đổ của cơ học.

Làm sạch Quái thú

Không một lần xả sạch đơn giản nào là đủ. Đây không phải là một cỗ máy thông thường - nó là một cỗ máy khổng lồ bằng sắt, thở bằng sự chính xác và mục đích. Bụi bẩn, cặn công nghiệp và mảnh vụn thường ẩn náu bên trong xe đẩy và móc treo - những bộ phận thiết yếu nuôi dưỡng toàn bộ tải trọng. Việc xả sạch hàng tuần là bắt buộc. Việc bỏ bê ở đây đồng nghĩa với việc để sự ăn mòn và nhiễm bẩn gặm nhấm các dây thần kinh của máy.

Mắt của Người Quan Sát

Sự sống còn phụ thuộc vào sự cảnh giác. Mỗi bình minh phải được đón nhận bằng một cái nhìn soi xét kỹ lưỡng - một nghi lễ nơi trực giác con người gặp gỡ gân cốt. Kiểm tra trực quan, thường bị bỏ qua vì vẻ ngoài đơn giản, thực chất lại là những người lính gác phòng ngừa thảm họa. Mọi mối hàn, tấm kim loại và khớp nối đều được quét. Ngay cả một vết nứt nhỏ nhất, nếu không được ghi chép lại, cũng có thể báo hiệu thảm họa dưới áp lực.

Bí tích bôi trơn

Khi cơ bắp gặp kim loại, nhiệt và ma sát trở thành những kẻ phá hoại thầm lặng. Bôi trơn là lời cầu nguyện thầm thì giữa các bộ phận, làm giảm căng thẳng giữa cột buồm và cần buồm, xe đẩy và bàn xoay. Một chế độ tra dầu tỉ mỉ không phải là tùy chọn - đó là sự sống còn nhờ sự uyển chuyển. Mỗi giọt dầu làm chậm lại quá trình entropy và cho phép khối đá nguyên khối cao chót vót này lướt đi thay vì bị nghiền nát.

Phục hồi cơ khí

Ẩn sâu trong mỗi chu kỳ là sự hao mòn cơ học. Kỹ thuật viên, giống như một bác sĩ với lớp da thép, phải thường xuyên chăm sóc các bộ phận bị hao mòn. Việc thay thế không chỉ là sửa chữa, mà còn là một nghi lễ đổi mới. Mặc dù một cần cẩu có thể hoạt động với các bộ phận bên trong bị hư hỏng, nhưng sự liều lĩnh như vậy sẽ dẫn đến tai họa. Cần cẩu hiện đại, được trang bị cảm biến và khả năng chẩn đoán nhạy bén, tự động tiết lộ những bệnh tật của chúng. Việc còn lại là con người phải lắng nghe tiếng gọi của chúng.

Xét xử bằng chuyển động

Sau khi kiểm tra, cần trục tháp được thử nghiệm vận hành. Cần gạt được kéo, tấm panel được ép - mọi chuyển động của nó phải hoàn hảo. Các chuyển động được giám sát bằng đôi mắt sắc bén, đôi tai lắng nghe nhịp điệu của máy móc. Người vận hành mặc áo giáp bảo hộ cá nhân (PPE) và thực hiện mọi bài kiểm tra theo đúng hướng dẫn của nhà sản xuất.

Việc duy trì khả năng vận hành của cần trục tháp không chỉ là một danh sách kiểm tra đơn thuần; đó là một nghi thức liên tục với những đánh giá tỉ mỉ, chẩn đoán phức tạp và hiệu chuẩn lại chính xác. Từ những cái nhìn lướt qua hàng ngày đến những cuộc đại tu kéo dài hàng thập kỷ, mỗi điểm kiểm tra tạm thời đều là một điểm tựa cho sự an toàn, sự tinh tế trong vận hành và độ bền kết cấu của những thiết bị khổng lồ trong ngành công nghiệp dọc này.

⫸ Cảnh giác hàng ngày: Nghi thức quan sát tinh tường

Mỗi bình minh mới đều đòi hỏi một con mắt sáng suốt.

-

Giám sát bề mặt: Kiểm tra mọi chi và dây chằng của cần cẩu để tìm rỉ sét, vết nứt nhỏ hoặc dấu hiệu mỏi cơ học báo hiệu những căn bệnh tiềm ẩn.

-

Kiểm tra dây cáp: Chú ý đến gân thép—tìm kiếm các chỗ bị rối, các sợi bị bung ra hoặc các điểm xoắn bất thường tiềm ẩn.

-

Đánh giá dịch sinh tồn:Chất làm mát, hệ thống thủy lực và chất bôi trơn phải phù hợp với ngưỡng tối ưu—sự mất cân bằng ở đây có thể dẫn đến hỏng hóc hàng loạt.

⫸ Những mưu đồ hàng tuần: Giữ cho gã khổng lồ luôn nhanh nhẹn

Mỗi tuần một lần, hãy đào sâu hơn.

-

Giảm ma sát: Tra dầu cẩn thận vào tất cả các điểm trục và khớp chuyển động để ngăn ngừa sự mài mòn.

-

Hiệu chuẩn hệ thống con: Kiểm tra khả năng phản hồi của bộ ly hợp, ma trận phanh và bộ truyền động chịu tải. Những sai sót nhỏ hôm nay có thể gây ra hậu quả nghiêm trọng vào ngày mai.

⫸ Khám hàng tháng: Kiểm tra mạch cấu trúc

Mỗi chu kỳ trăng đều đòi hỏi một cuộc điều tra nghiêm túc hơn.

-

Kiểm toán cơ chế bảo vệ:Từ bộ ngắt ngưỡng tải đến bộ bảo vệ chống va chạm—đảm bảo những người bảo vệ thầm lặng này luôn tỉnh táo và cảnh giác.

-

Đánh giá lại khung: Kiểm tra cột buồm cao, cánh buồm mũi duyên dáng và móc chắc chắn để tìm bất kỳ sai lệch về kiến trúc, xoắn hoặc vết lõm do kim loại.

⫸ Khám nghiệm tử thi hàng năm: Tòa án dị giáo công nghiệp

Việc đại tu hàng năm không phải là hình thức mà là khoa học phục hồi.

-

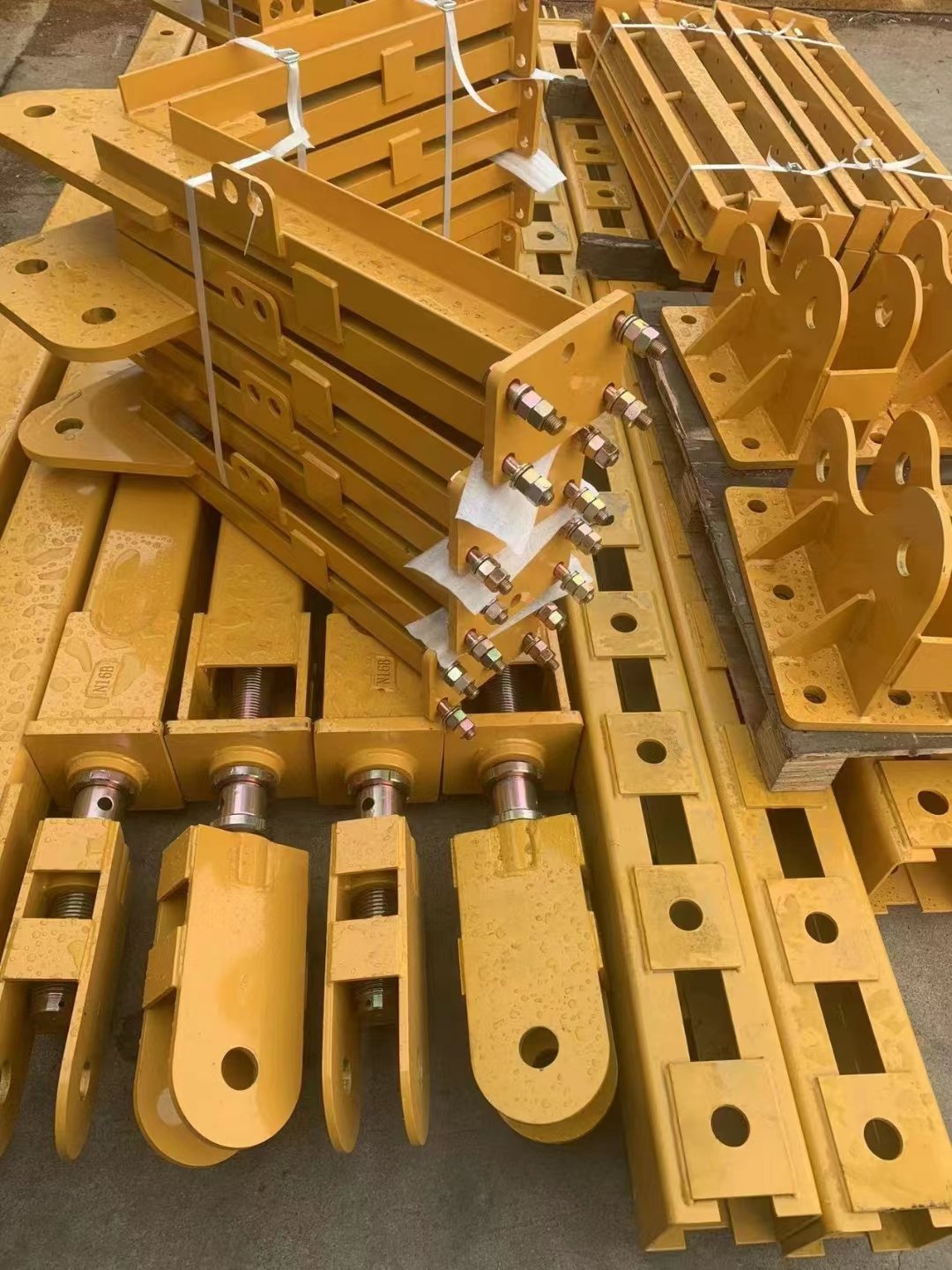

Tháo dỡ nội bộ: Tháo rời bộ phận quan trọng nhất. Vỏ hộp số, bộ biến mô và khớp nối quay sẽ được điều tra pháp y.

-

Phân tích hệ thống hoàn chỉnh: Kiểm tra kỹ mạng lưới thần kinh của cần cẩu—bảng điều khiển, công tắc giới hạn và cảm biến LMI phải khớp nối đồng bộ, không được phép có độ trễ.

⫸ Nghi lễ thập kỷ: Ngưỡng 10.000 giờ

Mười nghìn giờ hoặc một thập kỷ—tùy theo thời điểm nào đến trước, đều báo hiệu một nghi lễ thiêng liêng của sự đổi mới.

-

Đại tu toàn diện: Tháo rời, khử nhiễm, rèn lại. Bu lông, trục quay và từng ounce kim loại phải được kiểm tra lại để phát hiện những sai sót nhỏ.

-

Biên niên sử sử dụng: Căn chỉnh mọi hành động phục hồi theo đúng kinh thánh—học thuyết bảo trì ban đầu của nhà sản xuất.

⫸ Những trụ cột của nghề nuôi sếu thận trọng

-

Khai sáng cho người vận hành: Một chiếc cần cẩu chỉ có giá trị khi người quản lý nó xứng đáng. Người bảo quản được đào tạo bài bản sẽ ngăn ngừa tình trạng quá tải và kéo dài tuổi thọ của máy móc.

-

Học thuyết phòng ngừa:Bảo trì trước là sự khôn ngoan; sửa chữa sau tai họa là sự ăn năn.

-

Chẩn đoán im lặng:Sử dụng các phương pháp không phá hủy—siêu âm, kiểm tra hạt từ, chụp X-quang—để phát hiện những bất thường mà mắt thường không nhìn thấy được.

-

Thập tự chinh hai năm một lần:Mỗi nửa năm, hãy tiến hành kiểm toán toàn diện—xem xét kỹ lưỡng những điều chưa thấy, xác nhận những điều đã biết và chuẩn bị cho những điều chưa biết.

Thương hiệu cẩu tháp

Công suất cẩu tháp

![]()