Lịch sử và sự phát triển của cần cẩu tháp Liebherr

Câu chuyện sáng lập

Câu chuyện về cần cẩu tháp Liebherr bắt đầu vào năm 1949, khi Hans Liebherr cách mạng hóa ngành xây dựng bằng cách phát triển cần cẩu tháp di động đầu tiên. Sáng kiến của ông, ra đời tại Đức thời hậu chiến, đã đặt nền móng cho một trong những nhà sản xuất máy móc xây dựng hàng đầu thế giới. Cam kết của công ty về chất lượng và đổi mới vẫn không thay đổi kể từ những ngày đầu.

Các mốc quan trọng trong quá trình phát triển

Trong suốt lịch sử của mình, Liebherr đã đạt được nhiều khoảnh khắc đột phá. Những năm 1970 chứng kiến sự ra đời của cần cẩu thủy lực lắp dựng nhanh đầu tiên, trong khi những năm 1980 mang đến hệ thống điều khiển bằng máy tính. Mỗi thập kỷ đều đánh dấu những tiến bộ đáng kể về khả năng nâng, tầm với và sự tinh vi về công nghệ.

Các loại cẩu tháp Liebherr

Cần cẩu tháp quay trên

Cần cẩu xoay đỉnh là dòng sản phẩm chủ lực của Liebherr. Những cỗ máy mạnh mẽ này nổi bật với khả năng xoay 360 độ trên đỉnh tháp. Các mẫu như dòng EC-H có sức nâng vượt trội, từ 6 đến 40 tấn, lý tưởng cho các dự án xây dựng lớn.

Cần cẩu tháp lắp dựng nhanh

Dòng cần cẩu lắp dựng nhanh, bao gồm các mẫu phổ biến L1-24 và L1-32, cung cấp các giải pháp triển khai nhanh cho các dự án xây dựng vừa và nhỏ. Các cần cẩu này có thể hoạt động trong vòng vài giờ, mang lại hiệu quả đáng kể cho các dự án nhạy cảm về thời gian.

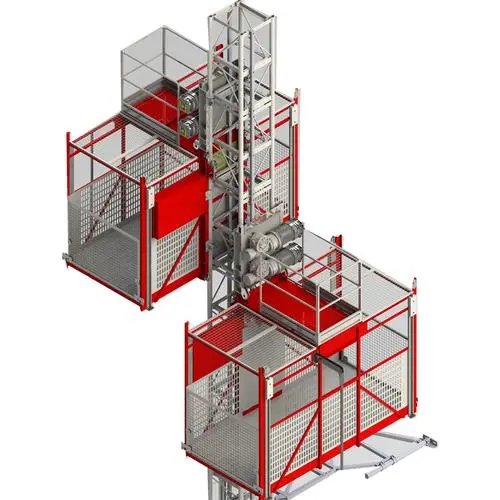

Cần cẩu xây dựng di động

Cần cẩu xây dựng di động của Liebherr kết hợp tính cơ động của cần cẩu thông thường với chức năng của cần cẩu tháp. Dòng MK minh họa cho tính linh hoạt này, mang lại thời gian lắp đặt nhanh chóng và khả năng nâng ấn tượng.

Tính năng kỹ thuật và cải tiến

Tải trọng và phạm vi tiếp cận

Cần cẩu tháp Liebherr được thiết kế để cung cấp hiệu suất tối ưu về cả khả năng chịu tải và tầm với. Các mẫu mới nhất có hệ thống cảm biến mô men tải tinh vi tự động điều chỉnh theo điều kiện làm việc, đảm bảo hiệu quả và an toàn tối đa.

Hệ thống an toàn của cần cẩu tháp Liebherr

An toàn vẫn là ưu tiên hàng đầu trong triết lý thiết kế của Liebherr. Cẩu tháp của họ tích hợp nhiều tính năng an toàn:

- Hệ thống chống va chạm

- Giám sát tốc độ gió

- Bộ giới hạn mô men tải

- Chức năng dừng khẩn cấp

- Hệ thống phanh dự phòng

Ứng dụng và trường hợp sử dụng của cần cẩu tháp Liebherr

Xây dựng nhà cao tầng

Trong lĩnh vực xây dựng nhà chọc trời, cần cẩu đã đóng vai trò quan trọng trong việc xây dựng một số công trình mang tính biểu tượng nhất thế giới. Các mô hình công suất lớn của chúng có thể hoạt động ở độ cao cực đại mà vẫn duy trì khả năng kiểm soát chính xác.

Dự án cơ sở hạ tầng

Từ cầu đến nhà máy điện, cần cẩu Liebherr đóng vai trò quan trọng trong phát triển cơ sở hạ tầng. Khả năng xử lý tải trọng nặng một cách chính xác khiến chúng trở nên không thể thiếu đối với các dự án phức tạp này.

Xây dựng công nghiệp

Tính linh hoạt của cần cẩu tháp Liebherr mở rộng sang xây dựng công nghiệp, nơi chúng xuất sắc trong việc lắp ráp các cơ sở sản xuất và kho bãi. Hệ thống điều khiển chính xác của chúng cho phép xử lý an toàn các thiết bị nhạy cảm.

Những cân nhắc về môi trường và tính bền vững

Hiệu quả năng lượng của cần cẩu tháp Liebherr

Liebherr đã có những bước tiến đáng kể trong việc giảm tác động môi trường của cần cẩu tháp. Hệ thống truyền động tiết kiệm năng lượng và quản lý năng lượng thông minh góp phần giảm chi phí vận hành và giảm lượng khí thải.

Tính năng thân thiện với môi trường

Các mẫu mới nhất tích hợp nhiều tính năng thân thiện với môi trường:

- Hệ thống phanh tái tạo

- Động cơ phát thải thấp

- Chất lỏng thủy lực phân hủy sinh học

- Công nghệ giảm tiếng ồn

Phần kết luận

Cẩu tháp Liebherr là sự kết hợp hoàn hảo giữa kỹ thuật xuất sắc của Đức và công nghệ tiên tiến. Sự phát triển không ngừng và khả năng thích ứng với nhu cầu xây dựng hiện đại đảm bảo chúng luôn dẫn đầu ngành. Dù là xây dựng thế hệ công trình bền vững tiếp theo hay hỗ trợ các dự án cơ sở hạ tầng quan trọng, cẩu tháp Liebherr vẫn luôn thiết lập tiêu chuẩn về độ tin cậy, an toàn và hiệu suất.

Những câu hỏi thường gặp

1. Sức nâng tối đa của cần cẩu tháp lớn nhất Liebherr là bao nhiêu?

Tháp cẩu Liebherr lớn nhất có thể nâng tới 125 tấn, tùy thuộc vào từng mẫu mã và cấu hình cụ thể.

2. Phải mất bao lâu để lắp ráp một tháp cẩu Liebherr?

Thời gian lắp ráp thay đổi tùy theo mẫu mã – cần trục dựng nhanh có thể hoạt động trong vòng 4-6 giờ, trong khi cần trục quay trên lớn hơn có thể mất 2-3 ngày.

3. Những tính năng an toàn tiêu chuẩn nào được trang bị trên cần trục tháp Liebherr?

Các tính năng an toàn tiêu chuẩn bao gồm hệ thống chống va chạm, giám sát gió, giới hạn mô men tải và chức năng dừng khẩn cấp.

4. Liebherr đảm bảo tính bền vững về môi trường cho cần cẩu của họ như thế nào?

Thông qua các hệ thống tiết kiệm năng lượng, vật liệu thân thiện với môi trường và công nghệ giảm phát thải.

5. Điều gì làm cho tháp cẩu Liebherr nổi bật hơn so với các đối thủ cạnh tranh?

Sự kết hợp giữa kỹ thuật Đức, công nghệ tiên tiến, các tính năng an toàn toàn diện và độ tin cậy hàng đầu trong ngành tạo nên sự khác biệt cho sản phẩm của họ.

Nếu bạn muốn đọc thêm thông tin về cách tăng lưu lượng truy cập vào Trang web của mình, chỉ cần truy cập –> www.used-towercrane.com

Thương hiệu cẩu tháp

Công suất cẩu tháp

![]()