Used XCMG6010 status: basic parameters introduction

The used XCMG tower crane 6010-6 factory date is 2021. Only used on one project, in good condition. Applicable to a variety of different construction objects, the independent fixed lifting height of 41m is attached to the lifting height of 180m; if attached to a height of more than 180m, the user needs to please specify when ordering that the lifting mechanism of the rope capacity needs to be increased.

»Basic Info«

| Luffing Type: | Flat Top Tower Crane | Internal number | xgp02-1 |

| Name brand: | XCMG | Model: | XGT6010-6 |

| Max. Load: | 6 Ton | Jib length: | 60 m |

| Load at jib end: | 1 Ton | Condition | Used |

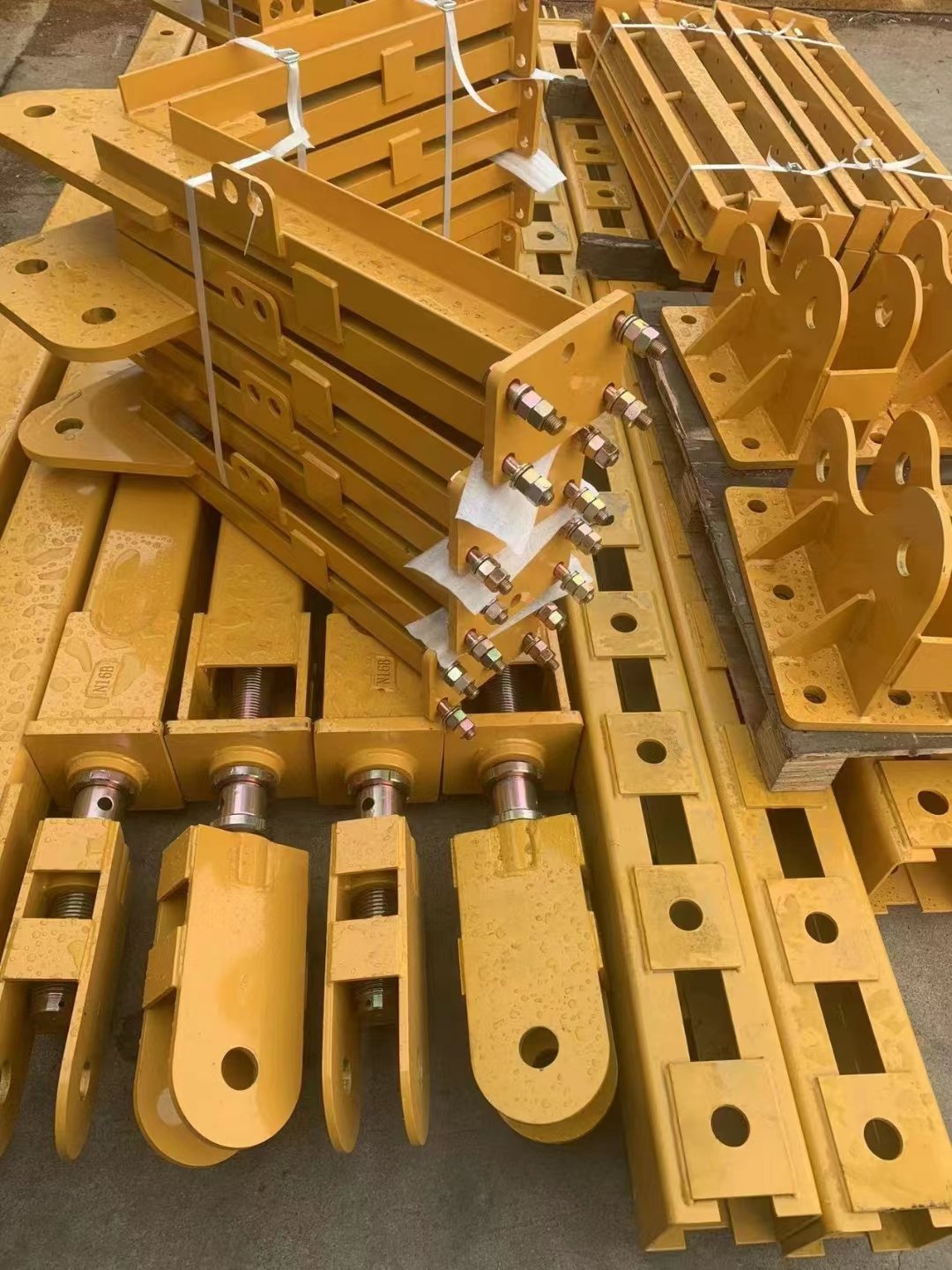

| Mast Section Size: | 1.6×1.6×2.8m | Year | 2021 |

| Free standing: | 41 m | Max. Standing: | 180 m |

»Detailed Photos«

» Conditions applicable to tower crane«

1) Working wind pressure (at the highest place): ≤250N/m2

2) Non-working wind pressure (at the highest place): ≤1100N/m2

3) Installation or jacking wind pressure (at the highest place): ≤100N/m2

4) Operating ambient temperature: -200C ~ 400C

5) Altitude: ≤1000 m

6) Power system: three-phase, five-wire system

Voltage: 380V, tolerance ±10%.

Power supply frequency: 50 Hz

7) Site power supply box: site power switch Ie ≥ 100A, installed at the bottom of the tower crane power inlet side from the standard section within 3 meters.

»Product Description«

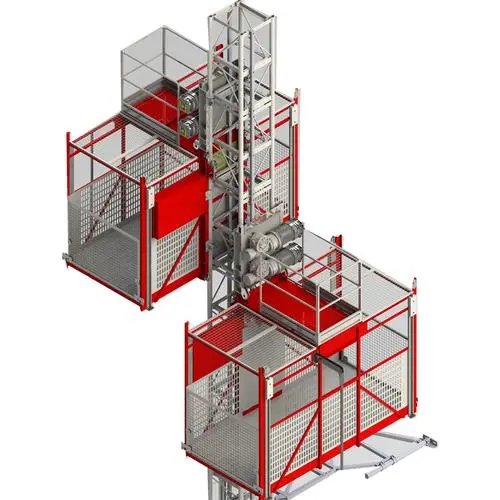

The XGT (6010Fz-6) tower crane is a horizontal lifting arm, trolley luffing, upper-slewing, self-elevating multi-purpose tower crane that features:

1. The performance parameters and technical indexes are leading in China. The maximum working range is 60 m, and the maximum lifting height is 180m.

2. The machine has independent fixed and attached working modes. Applicable to a variety of different construction objects, the independent fixed lifting height of 41m is attached to the lifting height of 180m; if attached to a height of more than 180m, the user needs to please specify when ordering that the lifting mechanism of the rope capacity needs to be increased.

3. The appearance of the whole machine is international, popular, beautiful, and loved by domestic and foreign users.

4. The working speed is high, the speed regulation performance is good, and the work is smooth and reliable.

5. The electrical control system adopts professional manufacturers to introduce foreign advanced technology in the production of electrical components. The life span is 3~4 times longer than domestic components. Fault-less, simple maintenance, reliable work.

6. Eight kinds of safety devices are equipped, and they are mechanical or electromechanical integration products, which can ensure the reliable work of the tower crane.

7. Designed to adhere to the national conditions and to ensure the principle of safety and reliability at the same time, as far as possible, absorbing the use of domestic and foreign mature and reliable advanced technology to improve the technical level of the machine, the use of mature and reliable advanced technology is:

1) The rotary mechanism adopts a planetary reducer equipped with hydraulic coupling, with high bearing capacity, smooth starting and braking, and reliable work, while the rotary mechanism can choose an imported frequency converter to achieve frequency stepless speed regulation, smooth starting and braking, no impact, safety, and reliability.

2) The professional electrical factory introduces Schneider’s technology to produce electrical components.

3) the introduction of foreign advanced technology and localization of the lifting capacity limiter, torque limiter, height limiter, amplitude limiter, slewing limiter, slewing, traction mechanism of the brake, and other safety devices.

4) trolley anti-break rope device (anti-skidding) and anti-break axle device.

5) Rope discharge system of the hoisting mechanism.

6) Traction rope tensioning system.

7) rigid double-tie rod suspension for large lifting arms, lifting arm stiffness, lightweight, small cross-section, small wind resistance, beautiful appearance, and several changes in length to meet different construction requirements.

8) The driver’s room is placed on the side; the field of vision is wide; the driver’s seat can be freely adjusted according to the human body’s needs; the operation is comfortable, creating a better working environment for the operator; the driver manipulates the action of each mechanism with the advanced linkage table; the operation is easy; and the maintenance is simple.

8. The design is in full compliance with or better than the relevant national standards.

Applicable to high-rise or super-high civil buildings, bridges, and water conservancy projects; large-span industrial plants; the use of slip-form construction of tall chimneys and silos; and other high tower-shaped construction projects.

![]()

1首图.jpg)